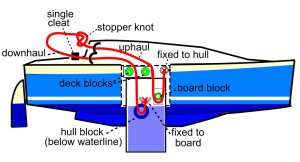

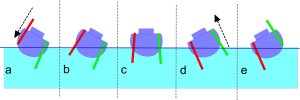

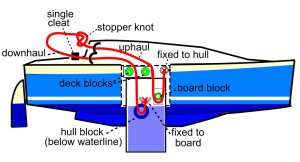

Here is a schematic showing the Vision lee-board lifting and lowering system. It is very different from the Red Fox 200 series that uses a purchase arrangement hanging from the mast shrouds.

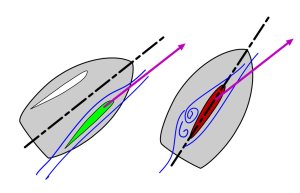

Imagine that the board was transparent in this picture – and the side of the slot in the hull cut away.

In the Vision there is a single line that loops back to the cockpit either side. One half of this is the uphaul for lifting – this goes forward through a fairline on the side of the cockpit then over a deck block and it runs around a block (about a third of the way down) on the board before being fixed to the hull back at deck level.

This board block never drops below the waterline. There is a stopper knot to limit how far down it can go. We also use a stopper knot through the hull ring. I’ll show that in the next post. Actually the board slot narrows at the bottom so the block can’t actually slip out. But it could be squeezed and damaged trying – that’s why the stopper knot is there.

The lee-board downhaul is the other side of the stopper knot. This goes down the aft of the slot (over a block) then around a hull block below the waterline and then back up to a fixing point on the board.

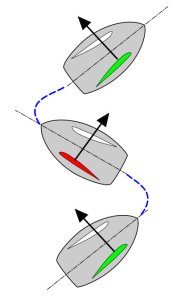

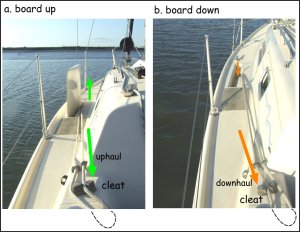

There is a single cleat that is used for either the uphaul or the downhaul. The uphaul is fixed tight in this with the board right up at anchor so it does not clunk in the night. The downhaul is fixed in it when the board is down as it is buoyant and needs to be forced down for the last foot below the keel depth.

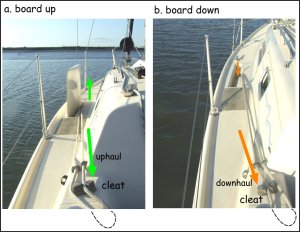

Here are photo showing those two cases – pulled right up (a) or cleated down (b) – the trick is to spot which side of the rope is cleated off.

In very heavy weather both boards should be cleated off either up (windward) or down (leeward) so that they would not slide in the case of a knockdown.

Like I mentioned in a previous post, once the boat has leaned on them with sails filled, then the boards are immovable even with a big effort – but I think that was the idea – the lifting ropes are meaty but I don’t think it would be fair on them to fix the board while it is under full pressure.

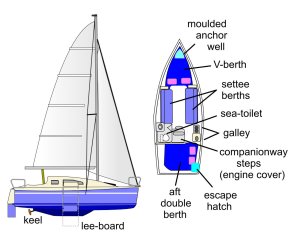

In the worst case of a grounding or impact on the lowered board then, although the board itself might take a hit, any damage to the hull would be in the moulding external to the interior of the boat – and above the waterline.

The part of this system that does not work as intended is the turning block below the waterline. On Swift, this is completely seized by seawater on both port and starboard – as you might expect. Fortunately the plastic wheel of this block is still nice and shiny and the wet rope slips easily around it. The rope keeps the plastic polished up. Maybe this was David Thomas’s plan after all…